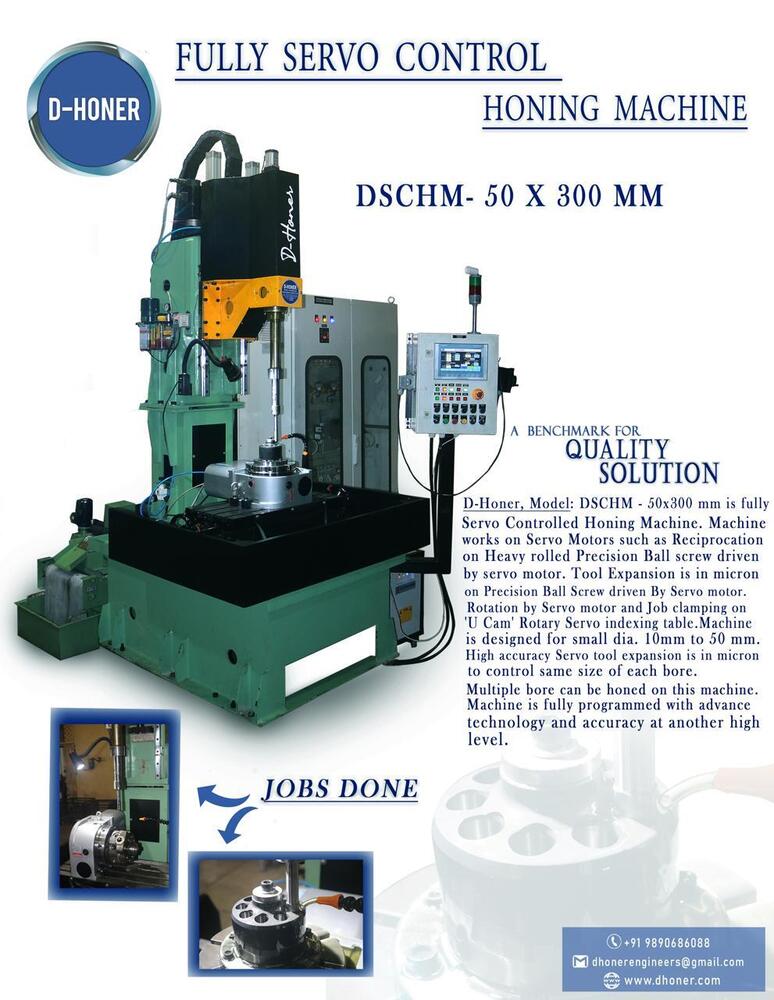

Fully Servo control honing machine

Fully Servo control honing machine Specification

- Drive

- Full Servo Drive

- Lubricating System

- Automatic Lubrication

- Motor Power

- 7.5 kW Servo Motor

- Model No

- FSH-1200

- Cooling System

- Integrated Coolant System

- Operating Temperature

- 5C to 45C

- Frequency

- 50/60 Hz

- Machine Type

- Servo Honing Machine

- Connectivity Options

- Ethernet / USB

- Features

- User-Friendly Interface, Digital Setting, Automatic Tool Compensation, Data Logging

- Control System

- Fully Servo PLC/Touchscreen

- Power Rating

- Three Phase

- Noise Level

- <75 dB

- Production Capacity

- Up to 100 pieces/hour

- Voltage

- 380V / 415V

- Frame Type

- Rigid Heavy Steel Frame

- Accuracy

- 2 m

- Product Type

- Fully Servo Control Honing Machine

- Technology

- CNC / PLC Controlled, Servo Automation

- Power Source

- Electric

- Operating Type

- Automatic

- Power

- 7.5 kW

- Pressure

- 0.6-1.2 MPa

- Surface Treatment

- Coated / Painted

- Dimension (L*W*H)

- 2200 x 1200 x 1800 mm

- Weight (kg)

- 1800 kg

- Color

- Blue / White

- Usage & Applications

- Precise internal diameter honing for automotive, hydraulic and aerospace components

- Software Update

- Remote via Ethernet

- Phase

- 3 Phase

- Material Compatibility

- Steel, Cast Iron, Aluminium, Brass

- Stroke Length

- Up to 400 mm

- User Access Levels

- Multi-tier Password Protection

- Spindle Speed

- 1002000 RPM (Variable)

- Display Type

- 7" HMI Color Touch Screen

- Tooling Range

- 6 mm 150 mm diameter

- Standards Compliance

- CE, ISO 9001:2015

- Floor Space Required

- Approx. 2.7 m

- Installation Service

- Available on Request

- Safety Features

- Emergency Stop, Overload Protection, Full Enclosure

- Memory Storage

- 1000+ program storage

Fully Servo control honing machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Others

- Supply Ability

- 3 Pieces Per Year

- Delivery Time

- 3 Months

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About Fully Servo control honing machine

A Fully Servo-Controlled Honing Machine is a state-of-the-art machining tool that uses servo motors to precisely control the entire honing process, allowing for high accuracy, flexibility, and efficiency. In this system, the key movements and parameters of the honing operationsuch as tool feed, tool speed, stroke length, and pressureare all controlled by servo motors, making the honing process highly adaptable and automated.

Key Features and Functions of a Fully Servo-Controlled Honing Machine:

1. Servo Motors for Precision Control:

- Fine-Tuned Movement: The use of servo motors allows precise control over every aspect of the honing process. This includes controlling the feed rate of the honing tool, the rotational speed of the tool, and even the pressure applied to the workpiece.

- Multiple Axis Control: Servo motors can control various axes of movement, including the horizontal and vertical feed of the honing tool, as well as rotational movements. This ensures a high degree of flexibility for complex parts and specific finish requirements.

- Adjustable Parameters: Servo motors allow the honing machine to automatically adjust and fine-tune settings like feed rates, pressure, and rotation speed in real-time. This helps maintain optimal conditions during the honing process and ensures high-quality finishes.

2. Adaptive Process Control:

- Real-Time Adjustments: The fully servo-controlled system can monitor and adjust key process parameters in real-time. For instance, if theres a change in workpiece material or tool wear, the system automatically compensates, adjusting the feed or pressure to maintain optimal performance.

- Consistency: With servo control, the honing process becomes highly repeatable, ensuring consistent surface finishes and dimensional accuracy from part to part. This is particularly important for mass production of precision components, such as engine cylinders and hydraulic bores.

3. Improved Surface Finish and Accuracy:

- High Precision: The machine can achieve tight tolerances and ultra-smooth finishes, which are crucial for applications in industries like automotive, aerospace, and hydraulic systems, where internal surface quality is critical.

- Uniform Material Removal: The servo-controlled system ensures that material is evenly and consistently removed from the workpiece, resulting in a uniform surface finish across the entire bore or cylinder.

4. Increased Flexibility and Versatility:

- Versatile for Different Parts: Fully servo-controlled honing machines can handle a variety of part sizes, shapes, and materials. The system can be easily reprogrammed to accommodate different workpieces, allowing manufacturers to produce a wide range of components with varying requirements.

- Customization: Operators can adjust parameters like honing pressure, tool speed, and stroke length to meet the specific needs of each part, making the machine highly adaptable for different production runs.

5. Tool Wear Compensation:

- Automatic Tool Monitoring: Servo control allows for continuous monitoring of the tools condition. If tool wear is detected, the machine can automatically adjust parameters to compensate, ensuring that the tool continues to perform optimally and the desired surface finish is maintained throughout the production run.

- Extended Tool Life: By continuously optimizing the process and adjusting for tool wear, the machine helps to extend tool life, reducing downtime and the frequency of tool changes.

6. Cycle Time Optimization:

- Faster and More Efficient: The ability to finely control the feed rates and pressures during the honing process leads to faster cycle times. The machine optimizes the honing operations, reducing overall production time while maintaining high precision and surface quality.

- Automation of the Process: The machine requires less manual intervention compared to traditional honing machines, reducing operator involvement and increasing overall throughput.

7. Integration with CNC or PLC Systems:

- Easy Programming: The machine typically integrates with CNC (Computer Numerical Control) or PLC (Programmable Logic Controller) systems, allowing operators to easily program the machine for different workpieces. Once programmed, the machine can perform complex tasks automatically, ensuring that the honing process is both efficient and precise.

- Remote Monitoring: Advanced systems often include features for remote monitoring, diagnostics, and adjustments, allowing operators to oversee the process from a distance and intervene only when necessary.

Applications:

A Fully Servo-Controlled Honing Machine is ideal for precision honing in a variety of industries, including:

- Automotive: Honing engine cylinders, transmission components, and valve guides, where precision and smooth internal surfaces are critical for performance.

- Aerospace: Finishing hydraulic actuators, fuel system components, and other high-performance parts that require smooth bores and tight tolerances.

- Hydraulic and Pneumatic Systems: Honing of hydraulic cylinders, pistons, and pumps for applications that require smooth, wear-resistant internal surfaces.

- General Manufacturing: For precision parts that require smooth internal surfaces, such as medical devices, industrial machinery, and pumps.

Advantages of a Fully Servo-Controlled Honing Machine:

-

High Precision and Consistency:

- The precise control of the servo motors ensures that every part is honed to exacting tolerances, resulting in consistently high-quality surface finishes and dimensional accuracy.

-

Reduced Setup Time:

- The ability to program and store different honing cycles for various parts reduces the time needed for retooling or setup between production runs, leading to faster changeovers.

-

Increased Productivity:

- Automation and real-time adjustments make the machine more efficient, reducing cycle times and increasing throughput. Additionally, the machines ability to handle different part types without manual intervention improves overall productivity.

-

Improved Tool Life:

- Servo-controlled systems continuously adjust process parameters to optimize tool performance, reducing unnecessary wear and extending tool life.

-

Minimized Human Error:

- The automated nature of the machine reduces the potential for human error, ensuring that the honing process remains consistent and repeatable across multiple production runs.

-

Cost-Effectiveness in the Long Run:

- While the initial cost of a fully servo-controlled honing machine may be higher, the improved productivity, reduced maintenance costs, and extended tool life make it a cost-effective solution for high-volume manufacturing operations.

Components of a Fully Servo-Controlled Honing Machine:

- Servo Motors: Provide precision control over the movement of the honing tool, feed rates, and tool pressure.

- CNC/PLC Control System: Allows for easy programming and monitoring of the honing process.

- Honing Head: Holds and adjusts the abrasive stones or brushes that perform the honing.

- Hydraulic or Pneumatic Systems: Provide consistent pressure for honing, working in conjunction with servo motors for precise control.

- Workpiece Fixturing: Securely holds the workpiece in place during the honing process.

- Coolant System: Keeps the tool and workpiece cool, helping to improve tool life and finish quality.

Conclusion:

A Fully Servo-Controlled Honing Machine represents the cutting edge of honing technology, combining servo motor precision with advanced automation to deliver high-quality, repeatable, and efficient honing processes. It is particularly valuable for industries requiring high-performance, high-precision components, such as automotive, aerospace, and hydraulic systems. With its ability to adapt to different parts and handle complex honing tasks with minimal human intervention, this machine offers significant advantages in terms of quality, productivity, and cost-effectiveness

High Precision and User-Friendly Control

Equipped with advanced CNC/PLC controls and servo automation, the Fully Servo Control Honing Machine enables effortless high-precision honing with an accuracy of 2 m. The intuitive 7" HMI color touchscreen provides digital setting, automatic tool compensation, and convenient data logging, empowering operators at all skill levels to achieve optimal results.

Versatile Applications and Robust Construction

This honing machine supports a broad tooling range and is suitable for processing steel, cast iron, aluminum, and brass. Its heavy steel frame ensures rigidity, while the integrated coolant and lubrication systems maintain consistent performance. It fits seamlessly into automotive, hydraulic, and aerospace manufacturing, handling up to 100 pieces per hour.

Comprehensive Safety and Connectivity Features

Safety is prioritized with emergency stop, overload protection, and full enclosure. The system also offers multi-tiered user access, secure data management, and can be updated remotely via Ethernet. Extensive connectivity options, including Ethernet and USB, make operation and maintenance efficient in modern production environments.

FAQ's of Fully Servo control honing machine:

Q: How does the Fully Servo Control Honing Machine ensure consistent accuracy during operation?

A: The machine utilizes servo automation with a closed-loop CNC/PLC control system and features such as automatic tool compensation and integrated digital settings. This ensures honing operations are performed with a high degree of precision, maintaining an accuracy of 2 m for every batch produced.Q: What materials and applications is this honing machine best suited for?

A: The machine is compatible with steel, cast iron, aluminium, and brass. It is ideal for precise internal diameter honing in automotive, hydraulic, and aerospace component manufacturing, where high accuracy and repeatability are critical.Q: When should the machine's software be updated, and how is the update process managed?

A: Software should be updated whenever new features or improvements are released. Updates are performed remotely via Ethernet, enabling quick and secure installation without interrupting regular production schedules.Q: Where can installation and after-sales support be obtained for this honing machine?

A: Installation service is available on request from the manufacturer, exporter, or supplier. Comprehensive support, training, and maintenance services are provided throughout India and internationally, ensuring optimal performance and uptime.Q: What safety mechanisms are integrated into the machine to protect operators during use?

A: Safety features include an emergency stop button, overload protection, full machine enclosure, and multi-level password protection. These measures safeguard operators during routine and intensive operations, complying with CE and ISO 9001:2015 standards.Q: How user-friendly is the operation interface, and who can access machine settings?

A: The 7" HMI color touchscreen interface is designed for ease of use, allowing operators to manage digital settings and data logging intuitively. Multi-tier password protection ensures only authorized personnel can access and modify machine parameters.Q: What are the main benefits of choosing this servo control honing machine in a production environment?

A: Key benefits include high throughput (up to 100 pieces/hour), precise and repeatable results, robust build quality, extensive program storage (over 1000 programs), enhanced safety features, automated lubrication, and modern connectivity options-resulting in higher efficiency and reduced downtime.

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 3 Pieces Per Year

- Delivery Time

- 3 Months

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vertical Honing Machine Category

Double Spindle Barrel Honing Machine

Minimum Order Quantity : 1 Piece

Power Source : Other, Electric

Product Type : Other, Double Spindle Barrel Honing Machine

Usage & Applications : Barrel internal surface finishing, Cylinder honing

Operating Type : Automatic

Surface Treatment : Other, Powder Coated

CNC Vertical Honing Machine

Minimum Order Quantity : 1 Piece

Power Source : Other, Electric

Product Type : Other, CNC Vertical Honing Machine

Usage & Applications : Precision honing of cylinders and hydraulic components

Operating Type : Automatic

Surface Treatment : Other, Paint Coated

Vertical Honing Machine 1500 strokes

Power Source : Other, Electric

Product Type : Other, Vertical Honing Machine

Usage & Applications : Honing of cylinder bores, sleeves, engine blocks, hydraulic cylinders, and precision engineering components

Operating Type : Automatic

Surface Treatment : Other, Polished / Rust Proof Coated

Single Spindle Vertical Honing Machine

Minimum Order Quantity : 1 Set

Power Source : Hydraulic

Product Type : Other

Usage & Applications : All types of cylinders.

Operating Type : Automatic

Surface Treatment : Painted