Manual Honing Tool

Manual Honing Tool Specification

- Cutting Speed

- Depends on manual operation

- Power Source

- Manual

- Spindle Speed

- Operator Controlled

- Tool Type

- Honing Tool

- Noise Level

- Low

- Application

- Internal surface finishing, deburring, cylinder honing

- Product Type

- Manual Honing Tool

- Material

- High Carbon Steel

- Computerized

- No

- Automatic Grade

- Manual

- Control System

- Hand Operated

- Drive Type

- Manual Hand Drive

- Weight (kg)

- Approx. 0.5 to 1.5 kg

- Dimension (L*W*H)

- Varies by model (Standard: 200 mm length)

- Capacity

- Suitable for small and medium bore sizes

- Feature

- Easy grip, replaceable stones, precise honing

- Color

- Metallic Grey with Black Handle

- Customizable Options

- Stone Grit, Handle Length

- Compliance

- Meets Industrial Standards

- Stone Type

- Replaceable Abrasive Stone

- Packaging Type

- Box or Blister Pack

- Honing Range

- 10 mm to 50 mm Diameter

- Heat Resistance

- High, suitable for extended use

- Usage Frequency

- Frequent, Suitable for Workshop Use

- Max Honing Diameter

- Up to 50 mm (model dependent)

- Stone Grit Range

- 80 to 600 Grit (Selectable)

- Suitable Material Workpiece

- Steel, Cast Iron, Brass, Aluminum

- Finish Achievable

- Mirror to Fine Finish

- Maintenance

- Low; Stone is replaceable

- Grip Type

- Ergonomic Non-slip Handle

- Corrosion Resistance

- Yes, anti-corrosive coating

Manual Honing Tool Trade Information

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Manual Honing Tool

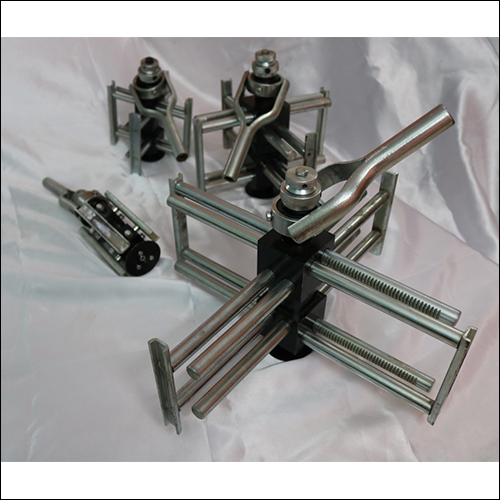

Unveiling a rare, peerless solution for precise surface finishingthe Manual Honing Tool featuring replaceable abrasive stones with selectable grit ranges from 80 to 600. Crafted from superb, meritorious high carbon steel, this tool guarantees high heat and corrosion resistance, suitable for frequent workshop use on steel, cast iron, brass, and aluminum. The ergonomic non-slip handle ensures user comfort, while its manual hand drive delivers an ephemeral mirror-like or fine finish. Customizable options and low-maintenance design make it a latest industry standard for internal honing up to 50 mm diameter.

Advantage & Special Features of Manual Honing Tool

Engineered for frequent professional use, this meritorious manual honing tool stands out for its easy grip, replaceable stones, and precise control. The ergonomic handle improves safety and comfort, while a wide range of selectable grits allows for superb customization in finishing work. Ideal for workshop environments, it is suitable for honing steel, cast iron, brass, and aluminum workpieces. Its high heat resistance and anti-corrosive coating guarantee reliability, even under extended use.

Delivery Time, Payment Terms, Certifications

With secure shipping arrangements and reputable goods transport partners, delivery of the manual honing tool is prompt, typically dispatched within 57 business days across India. Flexible payment terms include advance payment, bank transfer, and exchange options, ensuring convenience and transparency. This peerless product meets stringent industrial certifications for safety and performance, affirming its compliance with global quality standards and providing meritorious value to users.

Advantage & Special Features of Manual Honing Tool

Engineered for frequent professional use, this meritorious manual honing tool stands out for its easy grip, replaceable stones, and precise control. The ergonomic handle improves safety and comfort, while a wide range of selectable grits allows for superb customization in finishing work. Ideal for workshop environments, it is suitable for honing steel, cast iron, brass, and aluminum workpieces. Its high heat resistance and anti-corrosive coating guarantee reliability, even under extended use.

Delivery Time, Payment Terms, Certifications

With secure shipping arrangements and reputable goods transport partners, delivery of the manual honing tool is prompt, typically dispatched within 57 business days across India. Flexible payment terms include advance payment, bank transfer, and exchange options, ensuring convenience and transparency. This peerless product meets stringent industrial certifications for safety and performance, affirming its compliance with global quality standards and providing meritorious value to users.

FAQs of Manual Honing Tool:

Q: How do I select the appropriate stone grit for my honing application?

A: Assess the required surface finish: lower grits (80240) are ideal for deburring and rough finishing, while higher grits (320600) deliver a mirror or fine finish. Choose the grit based on material type and desired result.Q: What materials can I safely hone using this manual tool?

A: The tool is suitable for honing steel, cast iron, brass, and aluminum workpieces, making it versatile for most workshop finishing requirements.Q: When should I replace the abrasive stone in the honing tool?

A: Replace the stone when the honing performance declines or the grit surface becomes excessively worn to maintain optimal finishing and tool longevity.Q: Where can I use the manual honing tool most effectively?

A: This tool excels in workshop settings for internal surface finishing tasks, including cylinder honing, deburring, and precision work on small to medium bore sizes.Q: What is the process for customizing the tools handle length or stone grit?

A: Simply specify your preferred handle length and stone grit when placing an order. The manufacturer offers customizable options to suit your operational needs.Q: What are the main benefits of this manual honing tool?

A: The tool offers precise manual control, ergonomic comfort, easy maintenance, high heat and corrosion resistance, and adaptability for various metals, ensuring enduring, superb results.

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Honing Tools Category

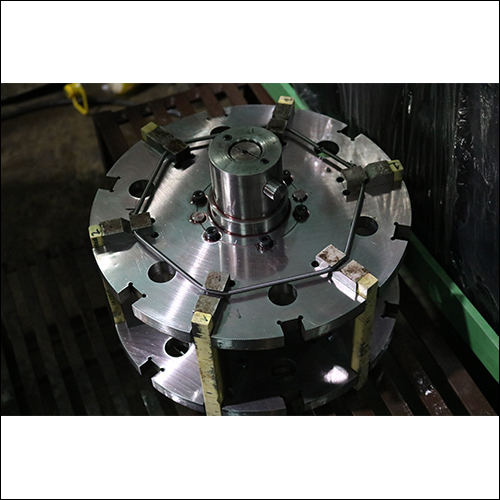

Manual Expansion Honing Tool Vertical

Automatic Grade : Manual

Product Type : Manual Expansion Honing Tool Vertical

Weight (kg) : Approx 8 15 Kg

Material : High Grade Tool Steel

Noise Level : Low

Tool Type : Vertical Honing Tool

Manual Expansion Honing Tool Horizontal

Automatic Grade : Manual

Product Type : Manual Expansion Honing Tool Horizontal

Weight (kg) : Approx 1.5 3.0 kg (Depends on model)

Material : Highgrade Alloy Steel

Noise Level : Low

Tool Type : Expansion Honing Tool