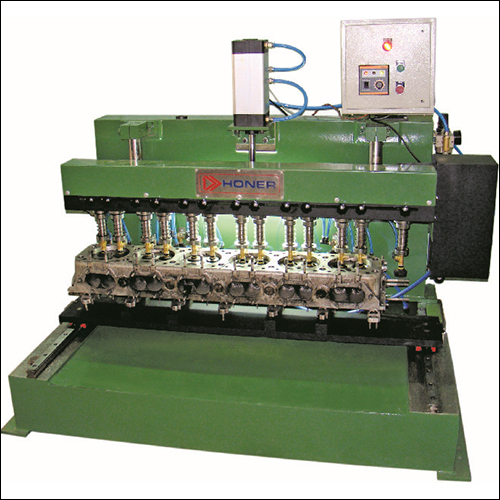

Face Polishing Machine

Face Polishing Machine Specification

- Accuracy

- High Precision Polishing

- Frequency

- 50 Hz

- Power Rating

- 1.5 kW

- Machine Type

- Bench Type Polisher

- Voltage

- 220 V

- Noise Level

- Below 75 dB

- Production Capacity

- 5-6 pieces/hour

- Features

- Heavy Duty, Reliable, Low Vibration, Portable

- Operating Temperature

- 0 40C

- Drive

- Belt Driven

- Motor Power

- 2 HP Induction

- Frame Type

- Mild Steel Rigid Frame

- Control System

- Push Button Panel

- Model No

- FPM-2024

- Connectivity Options

- Standard Electrical Connection

- Lubricating System

- Manual Grease Fitting

- Cooling System

- Integrated Water Supply

- Product Type

- Face Polishing Machine

- Technology

- Advanced Surface Polishing

- Power Source

- Electricity

- Operating Type

- Semi-Automatic

- Power

- 2 HP

- Pressure

- Manual Adjust (up to 20 kg)

- Surface Treatment

- Polished Finish

- Dimension (L*W*H)

- 1150 x 670 x 1200 mm

- Weight (kg)

- 220 kg

- Color

- Green & Silver

- Usage & Applications

- For Face Polishing of Tiles, Slabs, Metal, or Stones

- Compliance

- IS Standard Certified

- Installation Requirements

- Stable Flat Surface, 15A Socket

- Replaceable Parts

- Polishing Wheel, Water Nozzle, Drive Belt

- Packing Type

- Wooden Crate with Cushioning

- Operator Skill Level

- Basic Technical Knowledge

- Working Speed

- 1400 RPM

- Service Support

- Available Onsite and Remote

- Disc Diameter

- 250 mm

- Polishing Media

- Compatible with Resin, Diamond, and Felt Wheels

- Max Workpiece Size

- 600 x 600 mm

- Spindle Material

- Alloy Steel

- Safety Mechanism

- Emergency Stop Switch

Face Polishing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- Unit

- Main Export Market(s)

- Australia, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia, North America

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Face Polishing Machine

We are a quality conscious manufacturer, exporter and supplier of the best quality array of Face Polishing Machine. The offered machine is manufactured under the stern guidance of adept professionals as per set quality standards. Especially used for finishing and polishing of various automotive components, the provided machine is checked by quality experts on several aspects to ensure its smooth functioning. Moreover, our clients can purchase this Face Polishing Machine at economic prices from us.

Key points:

- User-friendly operations

- High performance

- Needs less maintenance

- Rugged design

Face Polishing Machine

Face Polishing Machine For Connecting Rods are of two forms such as first type traditionally called as grinding that involves rubbing a brittle material such as glass against a surface such as iron or glass itself with an abrasive such as aluminium oxide, emery, silicon carbide and diamond. This produces microscopic conchoidal fractures as the abrasive rolls about between the two surfaces and removes material from both. The other form of lapping involves a softer material for the lap, which is 'charged' with the abrasive. The lap is then used to cut a harder material the work piece.

The abrasive embeds within the softer material, which holds it and permits it to score across and cut the harder material. This will produce a polished surface such as a polishing cloth on an automobile, or a polishing cloth or polishing pitch upon glass or steel.

Versatile Application for Various Materials

This machine accommodates diverse polishing needs, making it suitable for tiles, slabs, metals, and stones. Its compatibility with multiple polishing media, including resin, diamond, and felt wheels, means its adaptable across industries. The maximum workpiece size of 600 x 600 mm allows for efficient processing of both large and small items while providing a high-quality, polished finish.

Safety and Reliability in Operation

Safety is prioritized with an emergency stop switch and manual pressure adjustment. The robust design and rigid mild steel frame minimize vibration and ensure operator stability. Installation requires only a stable flat surface and standard electrical connection. Service support is readily available both onsite and remotely, offering ongoing reliability for users.

Ease of Use and Maintenance

Designed with basic technical knowledge in mind, the Face Polishing Machine features a push button panel for straightforward control. Replaceable parts, such as the polishing wheel, water nozzle, and drive belt, simplify maintenance. Integrated water cooling and manual grease fitting ensure sustained performance and prolong machine life.

FAQs of Face Polishing Machine:

Q: How do I install the Face Polishing Machine correctly?

A: To install the machine, place it on a stable, flat surface and ensure access to a 15A electrical socket. Connect the standard electrical supply (220 V, 50 Hz) and verify that all replaceable parts are secure before initial operation. The machine arrives in a cushioned wooden crate for safe transport.Q: What materials and workpiece sizes can this machine polish?

A: The Face Polishing Machine can polish tiles, slabs, metals, and stones. It is designed to accommodate workpieces up to 600 x 600 mm and performs efficiently with resin, diamond, or felt polishing media, delivering a polished finish.Q: When should I replace the polishing wheel, water nozzle, or drive belt?

A: Replace these parts when you notice decreased polishing efficiency, visible wear, reduced water flow, or unusual belt noise. Regular inspection after each production cycle helps maintain optimal performance and machine longevity.Q: Where can I get service support for this machine?

A: Service support for installation, troubleshooting, and maintenance is available both onsite and remotely. Contact the manufacturer or supplier for assistance to ensure continuous and efficient operation.Q: What is the process for operating this machine?

A: After installation, secure the workpiece and select the appropriate polishing wheel and media. Adjust the manual pressure up to 20 kg as needed, power on the machine using the push button panel, and utilize the integrated water system for cooling during polishing. Monitor operation and use the emergency stop switch if required.Q: How does this machine benefit my production line?

A: It provides high-precision, efficient, and reliable polishing for various material surfaces, supporting a capacity of 5-6 pieces per hour. Its semi-automatic technology, low vibration, and heavy-duty design improve both productivity and product quality while ensuring operator safety.Q: What operator skills are required to use this machine?

A: Only basic technical knowledge is needed, making the machine accessible for most operators. Simple controls and straightforward maintenance procedures further ease the learning curve for new users.

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 2035531 Units

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Main Export Market(s)

- Australia, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia, North America

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lapping Machine Category

Both Side Lapping Machine

Minimum Order Quantity : 1 Number, ,

Color : Blue/White

Dimension (L*W*H) : 1600 x 1200 x 1700 mm

Surface Treatment : Other, Polished

Technology : Other, Precision Lapping

Operating Type : Other, SemiAutomatic

Valve Body Lapping Machine

Minimum Order Quantity : 1 Unit

Color : Industrial Grey

Dimension (L*W*H) : 1050 x 800 x 1350 mm

Surface Treatment : Other, Powder Coated

Technology : Other, Advanced Mechanical Lapping

Operating Type : Automatic

Bench Type Lapping Machine

Minimum Order Quantity : 1 Set

Color : Blue

Dimension (L*W*H) : 650 Millimeter (mm)

Surface Treatment : Coated

Technology : CNC

Operating Type : Manual